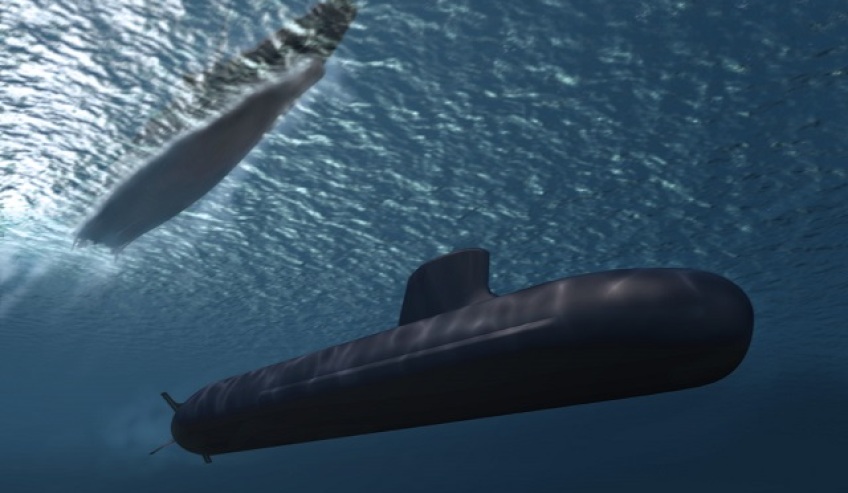

With more than half of the world’s submarines expected to be operating in our region in the coming decades, Australia’s surface warships and submarines require all the technological and industry advantages to ensure that they maintain their strategic and tactical edge.

To continue reading the rest of this article, please log in.

Create free account to get unlimited news articles and more!

While Thales has established itself as a key capability provider for Navy, the nation's domestic SMEs are key to providing and enhancing the capabilities of global primes.

As Australian industry gears up for the largest recapitalisation of Naval capability with the $80 billion SEA 1000 Future Submarine and $35 billion SEA 5000 Future Frigate programs, Thales is expanding the role that domestic SMEs play in enhancing the future anti-submarine warfare (ASW) capabilities of the nation's future naval platforms.

SEA 1000 capture lead for Thales Australia Adam Waldie highlighted the approach Thales is taking to engage with Australian industry to bring leading-edge ASW capability to Australia's future submarines.

"Thales has focused on building the local supply chain to help develop high-end industry capabilities with partners in Australia and New Zealand to ensure that we bring the capability Defence is asking. It is important that we focus not only on what is currently available, both government and Lockheed Martin want to see us leading research and development with our domestic industry partners to ensure that the when the platforms hit the water in the 2030s, they are leading edge," he said.

Thales is presenting the S2087 Sonar system currently employed by the Royal Navy for it's surface ships for the SEA 5000 program, particularly the Type 23 Frigates, widely recognised as one of the best ASW platforms in the world. To ensure commonality of capability between the surface and submarine fleets, Thales is planning on presenting a similar system for the SEA 1000 future submarine program.

Thales SEA 5000 capture lead David Eyles explained the importance of ensuring system commonality in the form of S2087, building on the system's history with the Royal Navy.

"The S2087 Variable Depth Sonar (VDS) currently operated by the Royal Navy, which is soon to be employed by the Royal Australian Navy will provide synergies across the SEA 1000 and SEA 5000 platforms to ensure that Navy has an integrated ASW capability," he said.

Domestic SMEs provide the flexibility in both operation, function and thought that larger companies like Thales can't match and this is one of the key advantages Thales has enjoyed through developing partnerships with Australian SMEs like Adelaide-based Airspeed Composites, which has landed a contract supporting the Thales global supply chain.

"SMEs operate differently and provide a wide range of individual and unique capabilities, we want to give back to our SME partners to improve out collaborative efforts. We've been around the country talking to SMEs about the opportunities provided by collaboration with Thales, not only for domestic projects, but also as a member of an integrated global supply chain so we can leverage these opportunities," Waldie and Eyles said.

Thales has used lessons from key programs like Bushmaster to inform future collaboration with SMEs, with Bushmaster seeing 80 per cent of work provided by Thales, with 20 per cent provided by Australian industry. Hawkei saw those figures reversed, providing the road map for projects like the SEA 1000 and SEA 5000 ASW projects.

"For us this is about developing the industry capacity over time road mapping to ensure that we provide Navy with the regionally superior ASW capability. Industry is a key part of delivering these new platforms, they aren't going to be delivered without industry involvement and that means uniformed service engagement and CASG working together to deliver these capabilities," Eyles said.

The full Defence Connect Podcast with Adam Waldie and David Eyles of Thales will be available shortly.

Login

Login