The Connecticut Center for Advanced Technology (CCAT) is a leading non-profit organisation providing integrated workforce development, research, development and commercialisation support and opportunities, creating and implementing bold ideas for applied technologies, energy solutions, STEM education, career development, and export and cyber compliance, with a key focus on supporting defence industry.

CCAT has some 300 customers and partners. It was created in 2004 and supports initiatives for small-to-medium-sized businesses and original equipment manufacturers (OEMs) in the areas of:

- Manufacturing and technology;

- Education;

- Workforce;

- Energy;

- Cyber security; and

- Export compliance.

Manufacturing: CCAT’s Advanced Manufacturing Center (AMC) supported more than 200 projects over the last 18 months, providing services related to additive and composite manufacturing, precision machining, scanning technology and applied engineering support.

These services are critical to the future health of Connecticut's various manufacturers, including:

- Sikorsky, a subsidiary of Lockheed Martin responsible for rotary aircraft, including the UH-60 Black Hawk and CH-53 Super Stallion series helicopters;

- General Dynamics Electric Boat, responsible for delivering the US Navy Virginia class Fast Attack Submarines and the new Columbia Class Ballistic Missile Submarines;

- United Technologies Corporation, parent company of Pratt & Whitney, responsible for delivering key aerospace components, including engines;

- Dexter Corp, an aerospace and electronics manufacturer; and

- Kaman Corp, advanced technology products.

Education: CCAT’s education efforts focus on developing and implementing context-based experiential programming that promotes STEM achievement and develops career awareness, through a variety of initiatives, including:

- CCAT’s CT Dream It. Do It. initiative is part of a nationwide campaign to create a positive image of today’s manufacturing and introduce students to the wide variety of interesting and well-paying careers the manufacturing field offers;

- A large part of CCAT's programming is directed toward urban youth in grades 5 through 9, a population that is most vulnerable when it comes to academic achievement and life success, and least likely to be aware of attainable educational and career pathways in manufacturing fields;

- In the summer of 2018, over 200 grade 7-9 students attended 10 two-week Young Manufacturers Academy programs throughout the state;

- Since 2015, 185 manufacturers throughout CT have participated in Dream It. Do It. events and/or hosted student groups for site visits;

- Each year, more than 450 middle and high students, educators, and manufacturers attend CT Dream It. Do It. events celebrating October Manufacturing Month;

- About 1,600 students in grades 5-8 participate in Hartford, East Hartford, Bloomfield and Manchester are participating in the Young Manufacturers Academy in-school program; and

- CT Dream It. Do It. also supports multiple manufacturing and STEM-themed events and career fairs around the state each year.

Workforce development: CCAT convenes an employer-led Advanced Manufacturing Employer Partnership with over 275 manufacturers. These manufacturers collaborate with educators, workforce development professionals and government agencies to recommend programs and services that help build the manufacturing talent pipeline.

CCAT's key workforce development support programs, include:

- Faciltating a pre-screening process for manufacturers, including Pratt & Whitney, that links qualified entry-level workers to jobs. The process framework begins with candidate recruitment through an online application portal, administration of assessments for math, reading, and mechanical aptitude, and one-on-one interviews to validate competencies and determine job readiness;

- Promoting a targeted program to recruit, screen and train women from communities with historically high unemployment among young adults for entry-level manufacturing positions;

- CCAT’s Advanced Manufacturing Center offers CNC Training basics classes to entry-level job seekers from CT’s urban areas;

- CCAT administers two credentials programs recognised by the National Association of Manufacturers – the National Career Readiness Certificate and the MSSC Certified Production Technician;

- CCAT is implementing an online manufacturing training curriculum to support a pre-apprenticeship pathway for both secondary and post-secondary cohorts; and

- CCAT’s Better Skills, Better Jobs initiative helps employers with job quality workforce issues that may be impacting their recruitment, training and retention through employee surveys, supervisory training and career coaching incumbent workers as needed.

Energy: Growing demand for renewable energy, battery storage and advanced energy options is another key area of focus for CCAT highlighting the role of industry diversity, with specific focus on:

- Assisting SME manufacturers to address their energy needs;

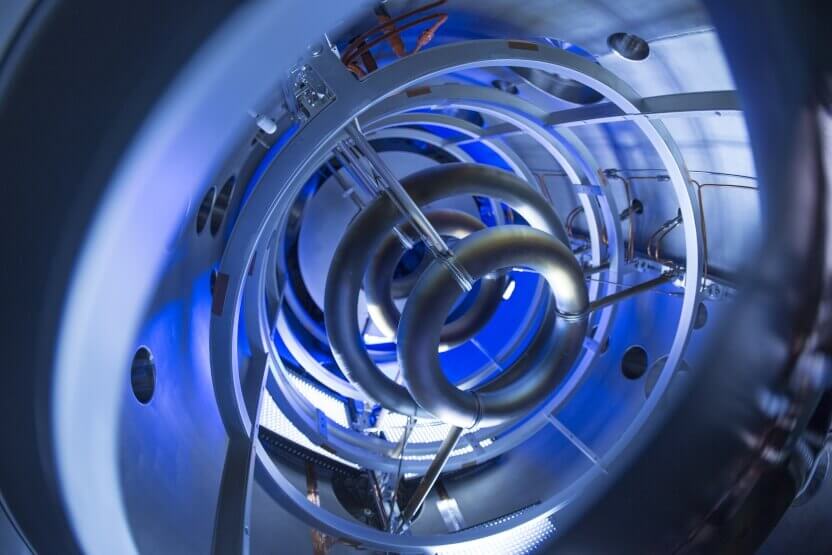

- Among its many energy programs, CCAT provides support for the Connecticut hydrogen fuel cell industry;

- Investment in the Connecticut Hydrogen Fuel Cell Coalition has supported clean power, renewable energy, zero emission transportation, reliable microgrids, distributed generation and grid reliability;

- The total regional economic impact for the hydrogen fuel cell industry has been recently estimated at $1.4 billion in revenue and investment, 6,620 full- and part-time jobs, and $615 million in labor income;

- Hydrogen and fuel cell industry impacts for CT:

- Total employment impact: more than 2,800 workers;

- Annual revenue and investment: $601 million;

- Labor income: $286 million annually;

- State and local taxes: $31 million to $47 million annually;

- CT is considered to be among the top places for industry development; and

- CT is at the core of a vibrant and strong cluster.

- Continued strategic support for the CT Hydrogen Fuel Cell Coalition by the state of Connecticut; and

- CCAT co-ordinates activities for work and support for CT businesses with various state and federal agencies including the state Department of Economic and Community Development, the state Department of Energy and Environmental Protection and US Department of Energy, the US Small Business Administration and the US Department of Commerce.

Cyber security: CCAT’s Advanced Manufacturing Center is developing best practices for cyber security on the shop floor and throughout the supply chain, with specific focus on developing key capabilities and support services for SMEs and OEM members:

- With two lawyers who are both certified US Export Control Officers; a wholly-owned, for-profit, 40-person IT subsidiary; and a 15,000 square foot Advanced Manufacturing Center, CCAT is uniquely positioned to provide export control and cyber security services to the manufacturing supply chain;

- CCAT partnered with the US Department of Commerce to develop a cyber security insurance resource for the manufacturing supply chain;

- CCAT provides products and services to enhance the manufacturing supply chain’s export control compliance program, including physical and electronic controls and protocols;

- Conducts cyber security assessments, develops plans of action and milestones, and system security plans, and implements the NIST 15 Basic Safeguarding requirements all required under the DFARs for defense contractors;

- CCAT hosted a round-table on the public/private partnership on cyber security with the UK Department of International Trade and its British Consul General, along with UTC, the US Attorney’s Office and RSL Fiber; and

- CCAT created a cyber security laboratory dedicated to manufacturing applications and training.

Export compliance: CCAT provides export support and best practice services for members, including:

- Helping companies to understand ITAR and EAR, and the many channels of federal regulations that govern export control can be critical to your company’s future, with specific focus on:

- The Department of State’s Directorate of Defense Trade Controls administers the International Traffic in Arms Regulations (ITAR), and the Department of Commerce’s Bureau of Industry and Security administers the Export Administration Regulations (EAR).

- Screening for export risks through due diligence best practice; and

- CCAT has a wholly-owned IT subsidiary with expertise in system security network administration, which can get businesses into compliance with the 15 basic safeguarding requirements with ease.

CCAT is also taking part in the 2018 USA-Australia Defense Trade Summit. This summit will bring together US and Australian aerospace, marine, cyber security, defence and supply chain companies.

It will also include educational institutions and representatives of the US and Australian departments of defense. Participants will discuss how to advance trade and business partnerships and how to build upon co-operation between large companies and the industrial supply chains in the two countries.

Companies attending can expect to hear from both countries on what they are procuring, industry breakout sessions to provide an overview of procurement opportunities and qualifications, multiple seminar sessions, as well as speakers from leadership roles in large OEMs/Tier 1s, US and Australian government officials, and industry experts.

More information on the structure, relationships and services of CCAT is available here. More information about the 2018 USA-Australia Defense Trade Summit is available here.