Kleos Space has announced the signing of a second MoU with Airbus Defence and Space, as both companies investigate opportunities to collaborate for the in-space manufacturing of structural elements.

To continue reading the rest of this article, please log in.

Create free account to get unlimited news articles and more!

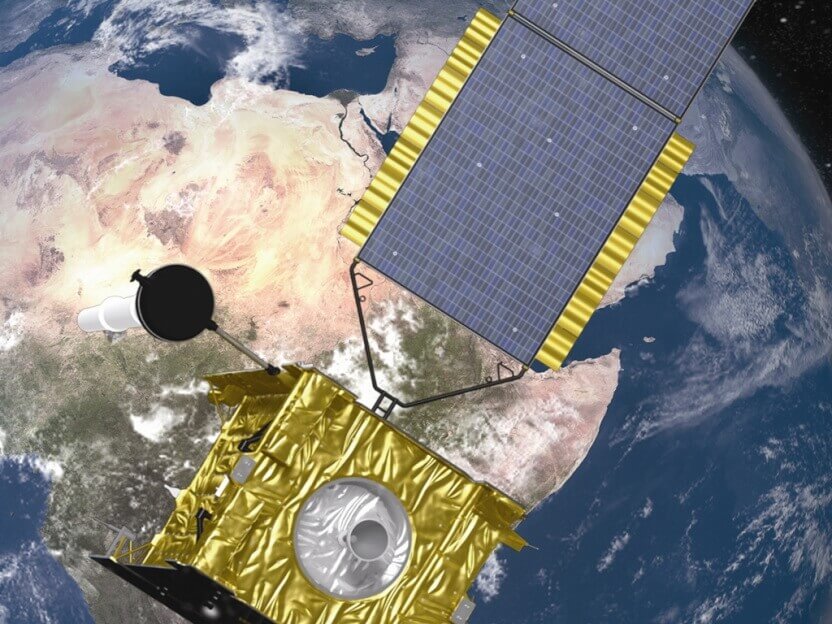

Kleos Space and parent Magna Parva (UK) have developed an in-space manufacturing system that will provide a method of producing huge carbon composite 3D structures in space. A prototype system has been successfully built and tested under ‘near space’ conditions at Kleos’ development facility.

This MoU demonstrates the potential for production of assemblies, equipment or even buildings from fully cured and consolidated carbon fibre materials, potentially miles in length.

The Kleos Space precision robotic technology manufactures 3D space structures using a supply of carbon fibres and a resin that is processed by 'pultrusion' through a heat forming die in a continuous process, producing cured carbon composite elements of extraordinary length. As the resin and materials behave differently in space, the development has included testing under both ambient atmospheric and vacuum conditions.

While pultrusion itself is an established manufacturing process, it has now been miniaturised down to a size where the equipment can be accommodated on spacecraft, and further work is under way to advance the technical readiness of the concept.

Airbus is currently investigating in-space manufacturing with a view to developing and accessing the required capabilities in Europe. In this capacity Airbus has agreed to support Kleos with guidance and expertise, enabling the development of applicable 3D structures.

Kleos Space, listed on the Australian Stock Exchange, is a space enabled, activity based intelligence, data as a service company and innovative in-space manufacturing technology developer based in Luxembourg.

Login

Login