Sydney-based Precision Metal Group (PMG) has signed a memorandum of understanding (MoU) to build the seating frames for the Australian Army’s new Boxer 8x8 combat reconnaissance vehicles.

To continue reading the rest of this article, please log in.

Create free account to get unlimited news articles and more!

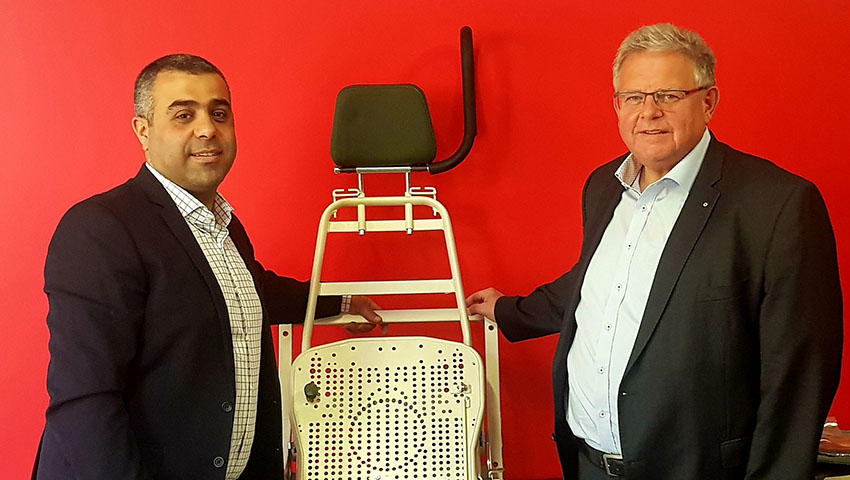

Precision Metal Group has partnered with German firm Probatec AG, which will support the local workforce of more than 50 employees based in Wetherill Park, NSW.

The partnership between Probatec and PMG will see the western Sydney-based company commence specialised product exports into Germany in early 2020.

It will also underpin an agreement between the two companies to work together – through technology transfer to Australia – to deliver seating for the fleet of Boxer CRVs Rheinmetall Defence Australia is delivering to the Commonwealth of Australia under the LAND 400 Phase 2 program.

Minister for Defence Linda Reynolds said the government’s $5.2 billion program for the acquisition and initial support period for the LAND 400 Phase 2 Mounted Combat Reconnaissance Capability will provide the Army with a world-class capability.

Military-grade seating is critical for the protection of soldiers positioned in the back of armoured combat vehicles. This seating, known as blast attenuation seating, prevents spinal compression injuries, protecting troops and the vehicle crew.

"These military-grade seats are critical for the protection of soldiers in our Boxer 8x8 combat reconnaissance vehicle crews. The vehicles are able to undertake a range of missions from regional stability and peacekeeping, through to high-threat operations," Minister Reynolds said.

PMG chief executive Jason Elias said the partnership with Probatec would expand the company’s footprint in defence industry globally and create jobs in western Sydney.

"Our agreement with Probatec establishes a local manufacturing capability that can deliver world-class seat parts and products that will protect soldiers in Australia and overseas. We have started testing and training our team to develop the products Probatec requires and expect to begin exporting parts to Germany by April this year," Elias said.

PMG is the first Australian company to achieve a German military welding certification – known as DIN2303 Q2 – and is growing rapidly as it expands its footprint in the Australian defence industry supply chain.

The company has already been announced as a supplier of products including battery boxes to the first 25 of the 211 Boxer vehicles Rheinmetall is delivering to the Australian Army under LAND 400 Phase 2.

Minister for Defence Industry Melissa Price said Precision Metal Group was a recognised success story for Australian industry, having already been contracted to supply the battery boxes for the Boxer vehicles.

"It’s fantastic to see Australian industry be part of producing a world-class capability for the Australian Army. This new partnership makes Precision Metal Group the first Australian company to achieve German welding certification, paving the way for further export opportunities," Minister Price said.

Elias added, "To become involved in AIC plans in the Australian defence industry contracts, many small and medium-sized enterprises (SMEs) will need to learn and understand the nature of the defence sector and adapt to the specific requirements in Australia to be successful moving forward."

Probatec is based at Amburg in Germany and has been a long-term supplier of military seating systems to Rheinmetall. Elias said gaining the DIN2303 Q2 certification enabled PMG to enter the international defence supply chain and establish contact with Probatec with a view to working together.

He said the PMG delegation also met with a number of other European companies currently delivering to defence forces internationally and gained an improved understanding of customer expectations around quality. These companies also included Amco Metal Services in Germany.

PMG has also ordered critical new manufacturing capability for delivery early in 2020 in line with the company’s strategy to increase the proportion of plant and equipment at Industry 4.0 technology levels of connectivity and automation.

Login

Login