BAE Systems Australia has announced a $4 million research and development partnership with the University of South Australia and Innovative Manufacturing Cooperative Research Centre to support the delivery of the Royal Australian Navy’s $35 billion Hunter Class frigates.

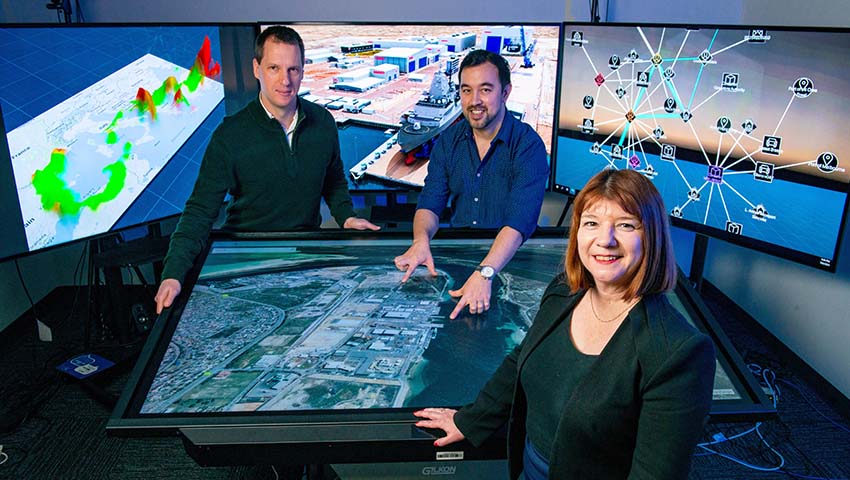

Australia’s Innovative Manufacturing Cooperative Research Centre (IMCRC), the University of South Australia (UniSA) and BAE Australia’s shipbuilding business, ASC Shipbuilding, are joining forces to fund data visualisation research that will prepare Australian industry for a future driven by digital innovation.

The research, which will be spearheaded by UniSA, will shape the development of digital manufacturing (Industry 4.0), improve shipyard planning and add unique data analytics and problem-solving capacity to the Hunter program, which will deliver nine world-leading anti-submarine frigates to the Royal Australian Navy.

IMCRC CEO and managing director David Chuter said the partnership will ensure the Hunter Class frigates are built using some of the most sophisticated innovations in manufacturing while developing extraordinary capabilities and ongoing capacity for Australian shipbuilding and manufacturing.

“This partnership will provide enduring and uniquely Australian sovereign industrial capability and advance and mobilise local manufacturers, particularly small and medium enterprises (SMEs), to support Australia’s naval shipbuilding strategy for generations to come,” Chuter explained.

Federal Minister for Industry Science and Technology Karen Andrews said the project represents innovation at its most powerful – embracing technology and a new way of doing things to improve production.

“Not only will harnessing data visualisation research help the Hunter program itself, it will also assist critical local supply chains and future projects across the manufacturing landscape,” Minister Andrews said.

The Hunter Class frigates will be the world’s first bow-to-stern digitally designed anti-submarine warfare frigate, and each ship involves highly complex supply chains.

ASC Shipbuilding’s continuous naval shipbuilding strategy director, Sharon Wilson, welcomes the opportunity to partner with UniSA and draw on the expertise of local researchers to drive innovation in digital manufacturing and find innovative solutions to production challenges.

“Digital shipbuilding is all about connectivity – not just within the physical and digital shipyard but with our supply chain and customer – and the research will support everyone and every single part and product on the Hunter program to be connected,” Wilson explained.

Wilson added, “Together we’re creating a first-of-its-kind digital environment through the entire ship design and construction to improve productivity, quality and safety outcomes in the shipyard, and underpin growth and longevity in the naval shipbuilding industry in Australia.”

UniSA chief collaborator, Professor Bruce Thomas, from the Australian Research Centre for Interactive and Virtual Environments, said the research will focus on how narrative visualisation and big data processing can deliver, reshape and refine the highly complex manufacturing environment across the time frame required for each frigate build.

Professor Thomas explained, “Fundamentally, the research project will be changing the way processes are carried out internally and externally to the shipyard. Through data fusion, machine learning and artificial intelligence data analytics, and visualisation technologies, we will be bringing intelligent planning systems and smart ‘human in the loop’ decision making to the project.

“What we learn by adapting, trialling and testing to suit the Hunter Class frigate’s design will support the prototyping later this year, but will also build significant knowledge for wider application in Australian manufacturing,” Professor Thomas added.

The nine Hunter Class frigates will be based on the BAE Systems Type 26 Global Combat Ship currently under construction for the Royal Navy and will replace the eight Anzac Class frigates when they enter service beginning in the late 2020s.

The Hunter Class is billed as an anti-submarine warfare (ASW) centric vessel delivering an advanced ASW capability to the Royal Australian Navy at a time when 50 percent of the world’s submarines will be operating in the Indo-Pacific region.

BAE Systems Australia announced that it had selected Lockheed Martin Australia and Saab Australia as combat systems integration industry partners, responsible for delivering the Australian-designed CEAFAR 2 Active Phased Array Radar, Lockheed Martin-designed Aegis combat management system and Saab Australia 9LV tactical interface.

The $35 billion program sees ASC Shipbuilding become a subsidiary of BAE Systems throughout the build process, beginning in 2020 at the Osborne Shipyard in South Australia, creating more than 4,000 jobs.

BAE Systems expects the Australian industry content for the Hunter Class build will be 65-70 per cent, which will create and secure thousands of jobs for decades.

At the end of the program, the Commonwealth will resume complete ownership of ASC Shipbuilding, thereby ensuring the retention in Australia of intellectual property, a highly skilled workforce and the associated equipment.

SEA 5000 is expected to support over 500 Australian businesses who have been pre-qualified to be part of the Hunter Class supply chain, with the Australian steel industry in particular benefitting from the 48,000 tonnes of steel required to build the ships.