The firms are set to explore ways to incorporate K-TIG’s welding technology in the local construction of Hanwha’s armoured vehicles.

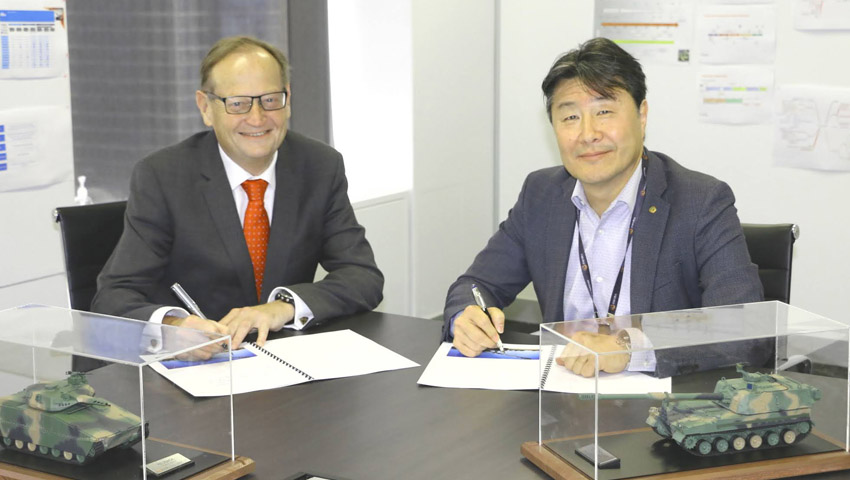

Hanwha Defense Australia and K-TIG Limited have signed a memorandum of understanding, which aims to examine how K-TIG’s welding processes can be applied to the construction of armoured vehicles in Australia and potentially overseas.

K-TIG’s welding process is designed to support at least seven millimetres of welding in a single run, reducing passes and preparation time by leveraging a high-energy density arc which results in modest heat transfer into the metal plates being joined.

This is expected to result in fewer distortions of the steel plates, while also reducing the chance of affecting the hardness of the armour.

“We are excited to work with K-TIG to establish how their advanced welding process can be utilised in the local manufacture of armoured vehicles,” Richard Cho, managing director of Hanwha Defense Australia, said.

“The potential for gains in quality and efficiency are significant. I am optimistic that we can utilise the K-TIG technology and help them further expand its applications to armoured vehicle production within the broader Hanwha group.”

Adrian Smith, managing director of K-TIG, added, “I am pleased that K-TIG is able to work closely with Hanwha to further commercialise our world-class Australian developed welding technology.

“We think we can help them supply the best possible product to the Australian Defence Force.

“K-TIG is also optimistic that Hanwha will adopt our technology for use in their programs in other parts of the world.”

[Related: Defence receives competing Hanwha, Rheinmetall IFV prototype]